In the realm of industrial machinery and conveyor systems, efficiency and reliability are paramount. The Powertwist stands as a testament to innovation in power transmission technology, offering a solution that outperforms traditional V-belts in numerous applications. From its unique design to its exceptional performance, let’s explore the world of Link Belt and explore how it’s shaping the future of power transmission.

The Genesis of Tab Link Belt Powertwist

Tab Link Belt emerged as a response to the limitations of conventional V-belts. Designed by Fenner Drives, a global leader in power transmission and motion control solutions, this revolutionary belt combines the flexibility of V-belts with the strength and durability of chain drives. The result is a product that delivers superior performance while minimizing maintenance requirements and downtime.

Innovative Design and Construction

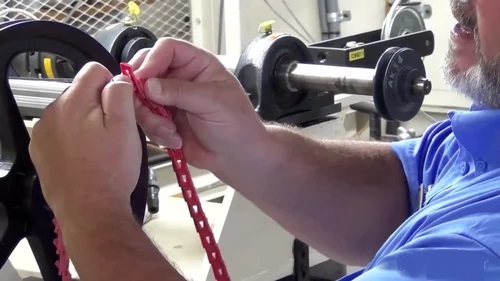

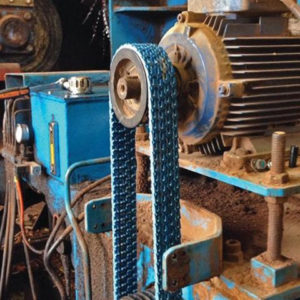

At the heart of Tab Link Belt lies its innovative construction. Unlike traditional V-belts, which rely on friction between the belt and pulleys for power transmission, it utilizes interlocking tabs that engage with specially designed sprockets. This unique design distributes power evenly across the belt, reducing wear and ensuring consistent performance over time.

Furthermore, Powertwist belts are constructed using high-quality materials such as polyurethane and polyester, imparting exceptional strength and durability. These belts can withstand harsh operating conditions, including extreme temperatures, moisture, and chemical exposure, making them ideal for a wide range of industrial applications.

Benefits and Advantages

The Tab Link Belt offers several distinct advantages over traditional power transmission solutions:

- Increased Efficiency: By minimizing slippage and power loss, these belts improve overall system efficiency, leading to energy savings and reduced operating costs.

- Enhanced Durability: With their robust construction and resistance to wear and tear, these belts outlast conventional V-belts, reducing maintenance requirements and downtime.

- Versatility: These belts are suitable for various applications, including conveyor systems, HVAC units, agricultural equipment, and more. Their flexibility allows for easy installation and adaptation to different configurations.

- Quiet Operation: Unlike chain drives, which can produce excessive noise during operation, belts operate quietly, creating a more comfortable working environment.

- Cost-Effective: Despite their initial investment, belts offer long-term cost savings due to their extended lifespan and reduced maintenance needs.

Application Across Industries

The versatility and performance of Tab Link Belt make it a preferred choice across a wide range of industries. From manufacturing and mining to agriculture and automotive, companies rely on these belts to keep their operations running smoothly and efficiently. Whether it’s conveying bulk materials, driving machinery, or powering HVAC systems, delivers consistent results day in and day out.

Lakhotia Conveyers Pvt Ltd: Your Partner in Power Transmission Solutions

As a leading provider of conveyor systems and power transmission solutions, Lakhotia Conveyers Pvt Ltd understands the importance of reliable and efficient equipment. With our extensive experience and expertise, we offer a comprehensive range of products and services tailored to meet the diverse needs of our customers. From Tab Link Belt to custom conveyor designs, we provide innovative solutions that optimize performance and productivity.

In conclusion, the Link Belt represents a paradigm shift in power transmission technology, offering unmatched reliability, efficiency, and versatility. As industries continue to evolve and demand higher standards of performance, these belts stand ready to meet the challenge, driving innovation and powering progress across the globe.